Maximizing PortaWell Flow Performance

PortaWell Admin

Author

Why Battery Chemistry and Filter Pressure Matter for Flow Performance in the PortaWell System

Introduction

Promotional literature for the PortaWell Starter Pak, PortaWell Mini and the PortaWell Triple portable water filtration system state that you can achieve flows up to 1 gallon per minute. But what does “up to” mean exactly and why is the qualifier even there.

All three PortaWell systems deliver 1 gallon (3.75 liters) per minute when the filters are cle

an (little of no fouling) and when the battery or power station is above 12.5 volts.

However, if the power source voltage falls below the 12.5 V-- either because of chemistry of the battery system you are using, or because the charging state of the battery is below the optimum operation level, the flow delivered by the pump could be less. The system pressure determined by the resistance of the filters and the line length of the output tubing also influences the overall flow rate. Clean filters, filters with low startup pressure and short length of out-let tubing all ensure a flowrate close to 1 gallon per minute. In simple terms:

- Clean filters + strong battery = full flow.

- Dirty filters + weak battery = reduced flow.

less-than-optimal battery, a partially discharged power station, or filters with high pressure drop can all cut flow by as much as 50%.

Power Meets Pressure

The ideal flow rate of the PortaWell systems is about 1 gallon (3.7 liters) per minute, far faster than other gravity-fed or hand pumped portable emergency water filtration systems.

System Backpressure

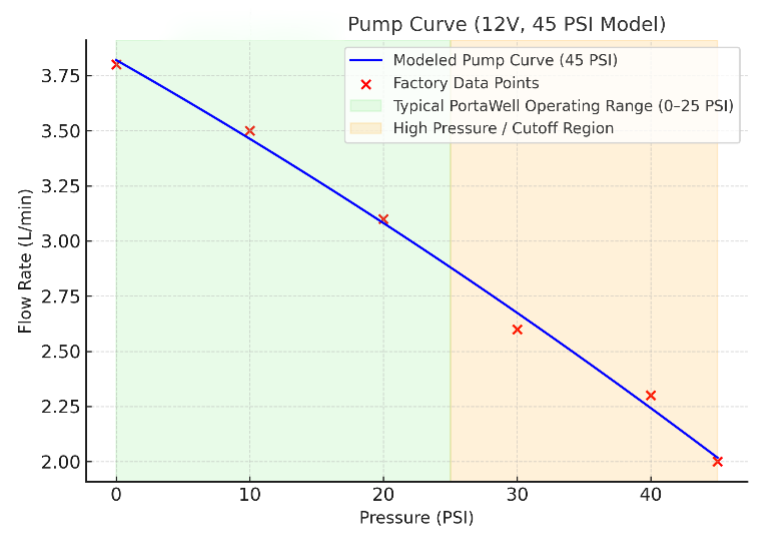

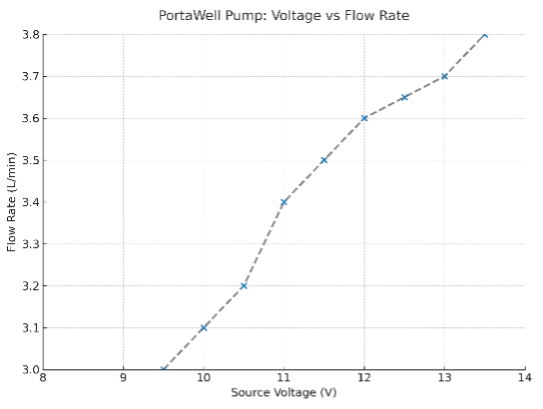

Figure 1 PortaWell Pump Curve

All filtration systems no matter what the power source obey a common principle, namely when the pores of the filter become clogged, the flow slows. With a hand-pump system, the pumping becomes harder until it is impossible to keep pumping. With a gravity fed system the flow slows to a trickle and eventually stops. It is the same with an electrically powered pump, except the flow volume follows a well-defined path called a pump curve. Figure 1 shows the curve of the pump used for all PortaWell systems. At zero or minimal backpressure, the pump delivers close to 1.0 gpm. As resistance increases—whether from filter clogging, denser filter media, or longer outlet tubing—flow gradually declines. Around 40 psi, the flow drops to about 0.5 gpm; a built-in pressure switch will stop pump operation above roughly 45–psi.

Battery Chemistry

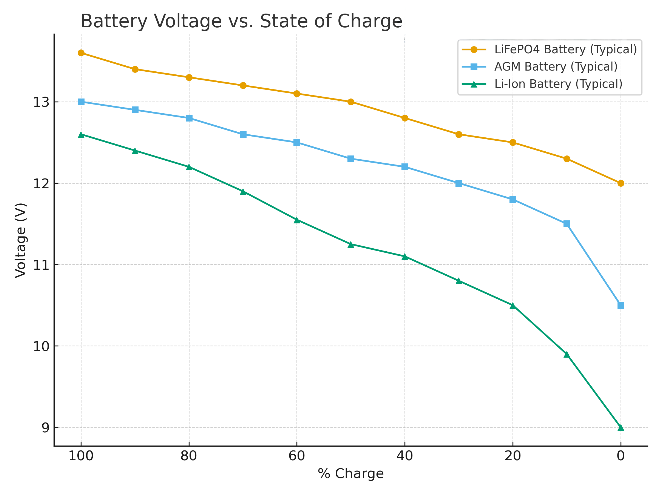

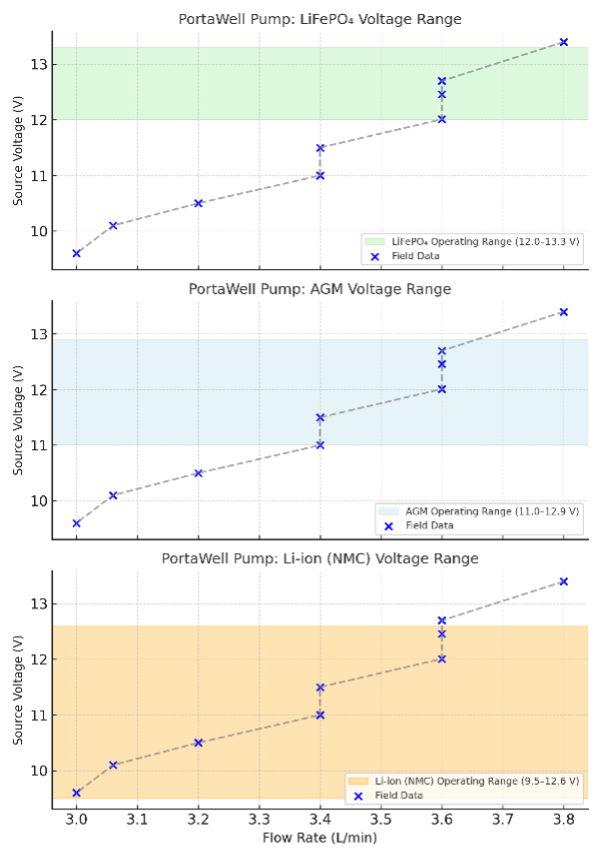

All rechargeable 12-volt batteries are not the same. While they may share the same nominal voltage, their actual operating ranges and discharge curves differ significantly by chemistry (see figure 2).

Figure 2 - Voltage Range of Battery Chemistry

Some chemistries track higher and some lower. The traditional 12-volt chemistry for rechargeable batteries is lead/acid. When fully charged it has a resting voltage of around 12.8 to 13.0 volts, and a fully discharged voltage of around 11 volts. The newer storage battery chemistries are Lithium-Ion (Li-Ion) and Lithium Iron Phosphate (LiPO4). Each covers a slightly different voltage range. The 12-volt LI-Ion battery has a fully charged resting voltage around 12.6 volts and a discharged voltage around 9.5 to 10 volts.

The 12-volt LiPO4 battery has a resting fully charged voltage of 13.6 volts and a discharged voltage of 12 volts. Table 1 shows the voltage range of each of the battery chemistries.

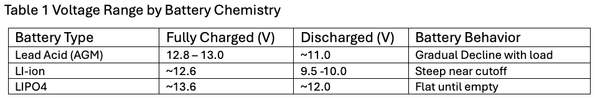

Table 1 Voltage Range by Battery Chemistry

Table 1 Voltage Range by Battery Chemistry

The PortaWell pump operates within the voltage range of 9.5 to 13.5 volts. Like all DC pumps, it spins faster and delivers higher flow at the upper end of this voltage range. At lower voltages, the pump speed and therefore flow—drops by about 25% (See figure 3).

Figure 3 Pump flow Rate vs Applied Voltage

Among these chemistries, LiFePO₄ stands out. It maintains a nearly constant voltage over most of its discharge curve, allowing the pump to sustain close to maximum flow much longer than AGM or Li-Ion batteries

Figure 4 is a composite that shows the effect of flow of all three chemistries with the conclusion that the LIPO4 chemistry sustains the highest flow over the useful charge/discharge battery range.

Figure 3 Flow vs Voltage Composite

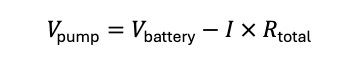

Voltage Drop Under Load

The voltage your pump actually sees is slightly lower than what you measure at the battery terminals. Current flowing through internal battery resistance and wiring causes voltage drop:

Voltage equation

For example, with a 3-amp pump draw and total circuit resistance around 0.15–0.25 Ω, voltage can drop 0.5–0.75 V under load.

That means a lead-acid battery measuring 12.0 V at rest may only deliver 11.3–11.5 V during operation—slightly reducing flow.

Real World Experience

While engineering models show potential 50% flow reductions under worst-case conditions, real-world performance is much better.

Using a 7 Ah AGM battery discharged to about 50% depth of discharge, the PortaWell system typically delivers 0.75 gpm—down only 25% from its full-voltage flow of 1.0 gpm. The pump draws roughly 3.0 A, and the running voltage stays near 11.6 V, indicating efficient operation well within the safe range.

Even with moderate voltage drop and rising filter pressure, the system continues to deliver usable flows and still far outperforming gravity or hand-pump systems under the same conditions.

Conclusion

Battery Selection:

For optimum performance:

- Use a LiFePO₄ battery or power station.

- Operate between 100% and 20% charge.

- Recharge when your display shows one bar or when voltage drops to about 12.5 V at rest.

This ensures full pump speed, stable flow, and extended battery life.

Filter Selection

- Two-stage setup: Sediment + NanoCeram — under 5 psi backpressure when clean.

- Three-stage setup: add Carbon or Aquametix — slight additional resistance.

- Ceramic second stage: higher starting backpressure (~20 psi) but cleanable for long-term use.

Final Take Away

For optimum performance from your PortaWell powered portable water filtration system it is recommended you use a power source (either standalone Battery or Power Station) that uses the Lithium Iron Phosphate (LiPO4) battery chemistry and operate it within the range of 100% to 20% of discharge. For Power stations that have a bar graph that usually means when it gets to 1 bar it is time to recharge. If using a voltmeter, this means a resting voltage of around 12.5 volts. This ensures the optimal performance of the pump as well as extends the useful life of the battery or power station by preventing over discharge.

Filter Selection

For the two-filter system the combination of sediment filter in the first stage and the NanoCeram in the second stage has a combined clean back pressure of less than 5 psi. Adding the carbon or Aquametix filter for the third stage increases the back pressure only slightly. Using a ceramic filter in the 2nd stage increases the starting back pressure to approximately 20 psi. While this has the advantage of being cleanable, it does impose a penalty by slightly reducing the flow.

PortaWell’s balance of electrical and hydraulic design isn’t accidental.

The pump, filters, and battery expectations are tuned as a system—so even as voltage and pressure vary, you still get strong, reliable flow when it matters most.

Engineering simplicity, field reliability, and consistent flow — that’s the PortaWell difference.